Construction Technologies

PRE-FABRICATED CONSTRUCTION COMPONENTS

MASS TIMBER FRAMING

Mass plywood panels (MPP), a new building product, were used for all horizontal framing on this project (glulam beams and posts were used for long spans at the street level garage); these panels were placed in about one day per floor, greatly reducing on site labor, and the overall construction schedule.

PRE-FABRICATED SHEAR COMPONENTS

The use of cold-formed steel MiTek-Hardy Frames for shear in this project not only allowed us to omit ALL exterior plywood sheathing, these panels were placed in about two hours per floor, greatly reducing on site labor, and the overall construction schedule.

PANELIZATION

Panelized, prefabricated wood stud wall framing, was used for all wall framing; these panels were placed in one to two days per floor, greatly reducing on site labor, and the overall construction schedule.

PRE-FABRICATED PLUMBING COMPONENTS

Rough plumbing components were also prefabricated, in both vertical and horizontal clusters, for standardized residential bathrooms, greatly reducing the amount of on-site labor.

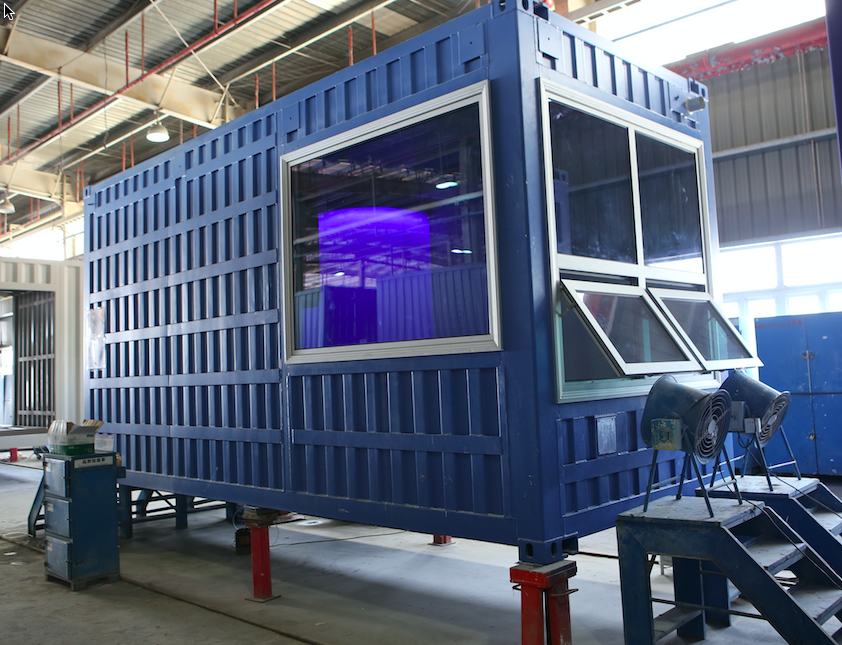

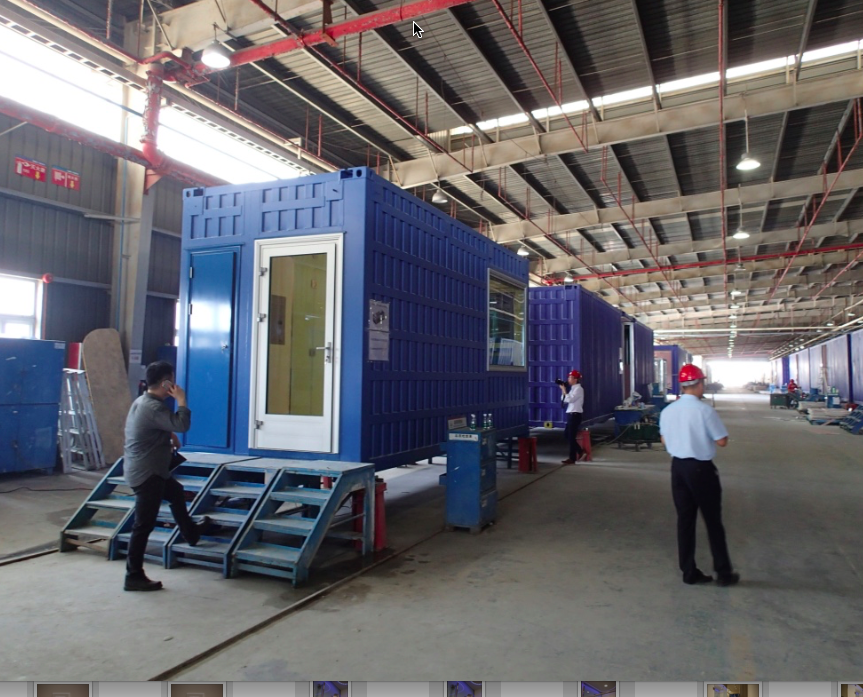

MODULAR CONSTRUCTION

The use of pre-fabricated modules, constructed in the controlled environment of an off-site manufacturing facility, are assembled together at the final building site, greatly reducing the amount of on-site labor.